Hybrid development tool for Clear-Rim technology

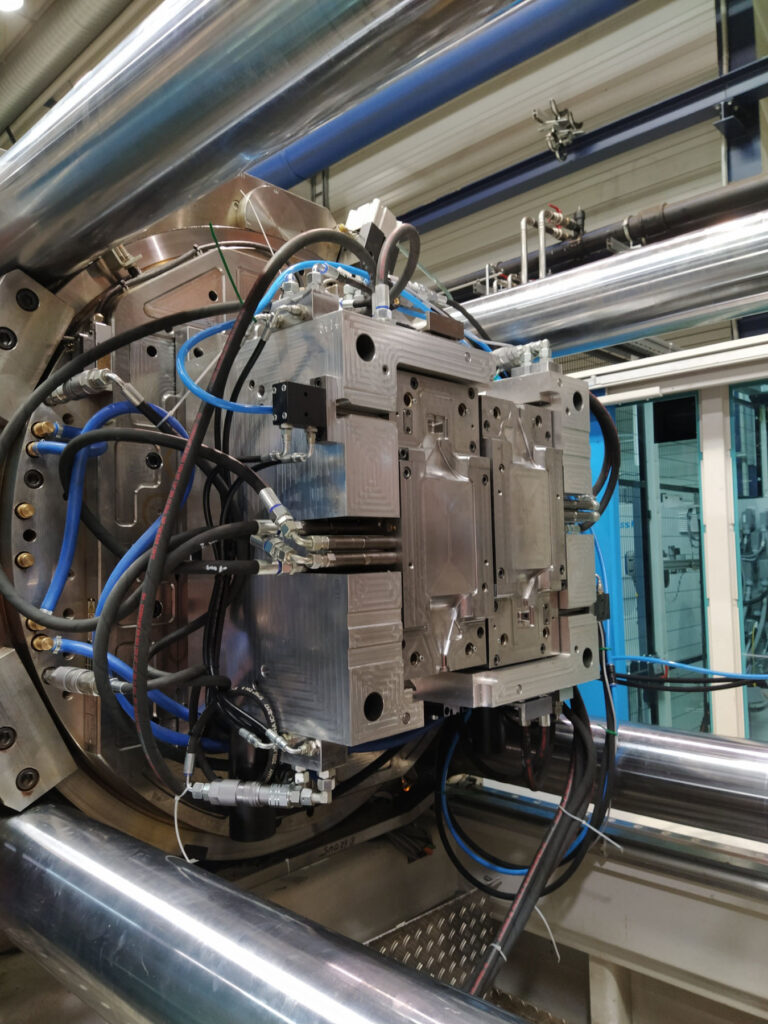

For a leading Tier-1 supplier we have produced a hybrid development tool for the clear-rim technology.

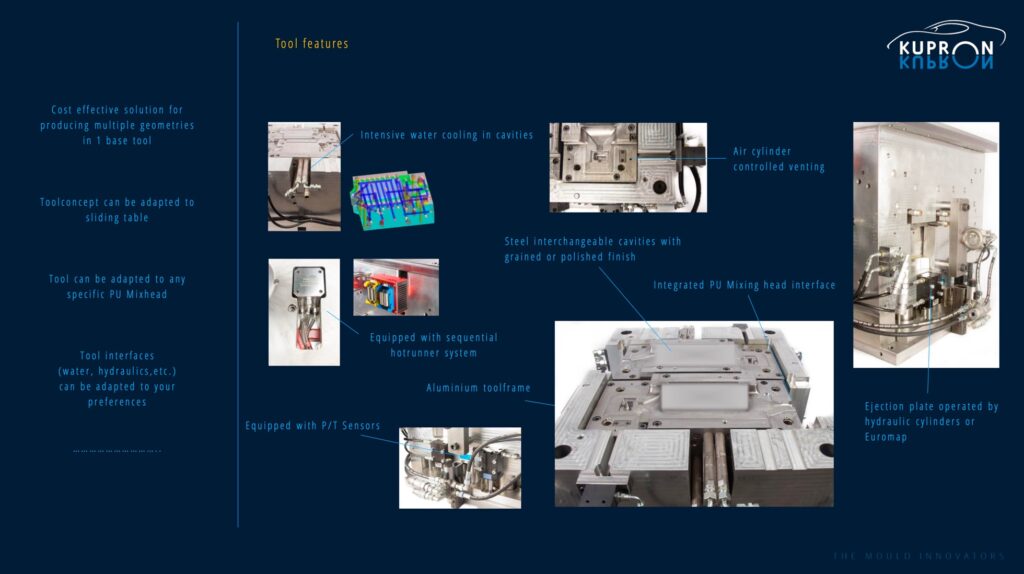

In this technology a thermoplast is overmoulded with a thin polyurethane coating. This coating ensures a high quality, scratch resistant surface for decorative parts. Without the need of an additional paint process.

The surface can be high gloss polished, but different kind of textures are also possible.

The whole process of producing and overmoulding the thermoplastic part takes place in one tool which makes the process very efficient.

Instead of making a tool completely out of steel or aluminium we have developed a hybrid solution in which steel is combined with aluminium. This leads to a commercially attractive solution with the surface quality of a steel tool. The steel inserts in this tool can be changed easily to change the geometry of the part without producing a completely new tool.

Below some pictures and further information about this tool:

This project is established together with our partners in the Fast Automotive Group. Within this alliance we are able to offer a turn key solution for this technology. From part design to processing and material selection.